Six years ago rolling stock manufacturer Vivarail began investigating the potential for battery train operation.

The company inherited some batteries from the Independently Powered Electric Multiple-Unit (IPEMU) battery train project in Essex, UK, then kitted out a carriage and set it to run around a test track at Long Marston, in Warwickshire, England, to see what it could do.

The old batteries, which had been laying in a shed for a few years, were able to run for 40 miles. This came as a surprise to Vivarail. It was at this point that the company saw that battery trains had real potential for the rail sector and a new project division was set up purely to develop traction batteries. Working closely with its supplier, Hoppecke, the division spent more than two years in R&D, and today has batteries that can achieve approximately 80 miles in range.

Regulators were always involved and all elements of risk fully understood. That task was successfully achieved and the next step identified – a year-long live trial on the national network. With assistance from the UK’s Department for Transport and Network Rail, Fast Charge’s trial is due to start in early 2022 on the West Ealing-Greenford line in London, after that it will be fully approved for use on the network for all types of battery train.

Of course, as well as Fast Charge, batteries can be charged by a variety of methods and Vivarail has already built a set of battery hybrid trains for Transport for Wales, again the first of their kind in the UK. These trains consist of three carriages, the driving cars holding two batteries and the middle car with diesel generators. The batteries are the primary source of traction with the generators charging them. The batteries can also capture the regenerative energy created when braking. As part of its green ethos Vivarail has designed a geofencing system so the generators are switched off entirely in sensitive locations, such as stations and close to housing.

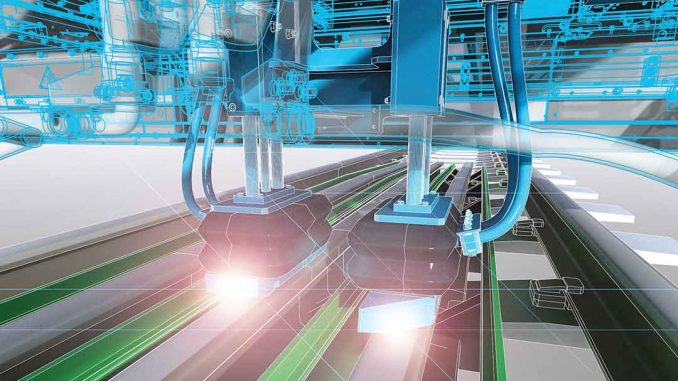

Part of the beauty of batteries is their flexibility – they are happy to accept power According to Vivarail, the Fast Charge application is quite simple. Lengths of conductor rail sit between the running rails. Beside the track is a container full of batteries (the company aims to use second-hand batteries in power storage banks, possibly from the automotive industry). All the train has to do is pull to a stop in its normal place. At that point, and without any need for the driver to do anything, a high current shoegear connects to the conductor rail. An electronic handshake takes place to ensure it is the right train in the right place and at the right time. Once all the safety checks have been made by the train and track systems, the train then dictates how much power it needs. The batteries are monitored constantly, with each cell being checked by the battery management system, and the train knows exactly what it needs to replenish and balance its on-board batteries. Fast Charge is able to recharge a train to full power in less than 10 minutes.

The first demonstration of the technology took place in 2019 with Innovate UK in attendance. Fast Charge has been developed with the support of a grant from Innovate, which helped move it from concept to reality. Due to the potential of Fast Charge, Innovate UK still considers it to be one of its most successful investments.

Vivarail’s current battery hybrid design is equally suited to hydrogen fuel cells as it is to a traditional genset. Furthermore, the modular nature of the train means existing units can be upgraded as new technologies come on stream. In terms of maintenance, the modular system means that if there are failures parts can be swapped out in around 10 minutes.

Its own technology package of traction systems, batteries, power storage banks and Fast Charge can combine to retraction good quality diesel trains – as proved by the Vivarail Class 230 trains – and also to act as range extenders for other types of electric trains. The company is actively working on projects in the UK and Europe where there is a wealth of stock prime for conversion.

Vivarail credits its success to its ability to move quickly and proactively. Within six years of set-up it has sold fleets of trains to West Midlands Railway, Transport for Wales and South Western Railway in the UK. More excitingly, it has become the first UK company to export battery trains, having supplied a first unit to the Railroad Development Corporation (RDC), to create the new Pop-Up Metro rail solution for the US, where battery trains will slot in as shuttles into city centers. RDC has now ordered two further cars and Vivarail is due to deliver those at the end of 2021.

The team is currently building a next-generation battery train, which is set to launch at the UN Climate Change Conference, COP26, in Glasgow in November this year. This train will be running out daily from Glasgow Central to demonstrate what batteries can do today.

Source: https://vivarail.co.uk/fast-charge-recharging-a-train-to-full-power-in-10-minutes/