- ritishvolt has selected BTR as its key synthetic graphite and silicon oxide supplier, with processing powered on clean, renewable hydroelectricity

- The news follows on from securing a portion of its cobalt requirements from strategic partner Glencore and the recent announcement of a JV with Indonesia’s VKTR for nickel sulfate; all perfectly in tune with the Britishvolt business plan of security of raw materials supply to ensure manufacture of low carbon battery cells

- BTR plans to build a sustainable manufacturing footprint in Europe

Northumberland, [28/07/2022]:

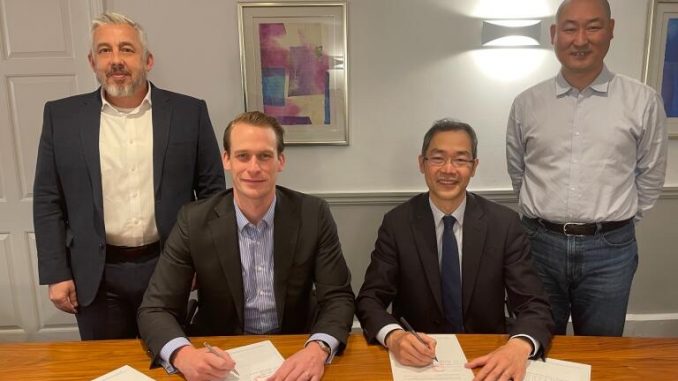

Battery technology pioneer Britishvolt has signed a Memorandum of Understanding [MoU] with BTR for the supply of synthetic graphite and silicon oxide to be used in selected phases of its battery manufacturing processes.

The anode material will be produced using renewable energy and is aligned with the company’s desire to select the very best materials and develop partnerships with world class suppliers.

BTR plans to build a sustainable manufacturing footprint in Europe that will, not only, bring the production of these materials closer to the Britishvolt Gigaplant in Northeast England, but also reduce embedded carbon in Britishvolt’s supply chain and utilise base materials from upstream supply chains in the UK.

“I am delighted to announce this partnership with one of the industry’s very best suppliers. Not only do we benefit from the technical expertise of BTR, now and in the future, but we also benefit from their global strategy concerning their manufacturing location and up- stream material plans. We were always committed to shape global supply chains, and with this collaboration with BTR we are achieving that.”

Timon Orlob, Global Chief Operating officer, Britishvolt

Security of supply remains a hot topic, and the news follows other strategic agreements made by the battery cell manufacturer.

Graphite production is hugely energy intensive, much like the bulk of the battery manufacturing industry, and it is essential to use renewable energy to produce batteries that are truly sustainable and low carbon.

Britishvolt has already signed MoUs with four separate OEMs, including Lotus and Aston Martin, which have cumulative demand in excess of 6GWh in 2025, and set the stage for the full 38GWh factory capacity that will be supplied annually from its Gigaplant site in Northumberland.

Britishvolt have already developed successful A Samples and is scaling up its unique cell formulations at UKBIC in Coventry and will also have its own scale up facilities from 2023 at Hams Hall in the Midlands, UK.

Release of official A-sample battery cells to customers, which is scheduled in 2022, will help to further accelerate commitments.

Notes to Editors

For more information please contact:

Ben Kilbey, Britishvolt’s Chief Communications Officer:

ben.kilbey@britishvolt.com +44 7305 032904

About Britishvolt

Battery pioneer and technology innovator, Britishvolt, is focused on development of next-generation battery cell technologies and associated research and development. It is dedicated to developing the future of electrified transportation and sustainable energy storage, producing best-in-class, low-carbon, sustainable, responsibly manufactured lithium-ion battery solutions. Not all batteries are created equal.

Her Majesty’s UK Government announced on January 21, 2022, its support for Britishvolt from its Automotive Transformation Fund delivered by the Advanced Propulsion Centre.

Britishvolt acquired battery cell developer and manufacturer, EAS, in May 2022, that will allow it to develop and scale up its larger 46xx high-performance cell formats and get them to customers quicker and more efficiently. The deal is subject to completion and any regulatory approvals.

Britishvolt believes that low carbon, sustainable, responsibly manufactured battery cells can help positively change the planet. The time has come to transition from fossil fuels to clean, renewable, low carbon electricity. The world deserves a clean air future for all.

About BTR:

Safe Harbour.

Certain statements in this press release concerning our future growth prospects are forward-looking statements regarding our future business expectation intended to qualify for the ‘safe harbor’ under the U.S. Private Securities Reform Act of 1995, which involve a number of risks and uncertainties that could cause actual results to differ materially from those in such forward-looking statements.

The risks and uncertainties relating to these statements include, but are not limited to, risks and uncertainties regarding fluctuations in earnings, fluctuations in foreign exchange rates, our ability to manage growth, competition including those factors which may affect our cost advantage, equipment procurement, wage increases, our ability to attract and retain highly skilled professionals, time and cost overruns on fixed-price, fixed-time contracts or time and material construction contracts, customer concentration, restrictions on immigration, industry segment concentration, our ability to manage international operations, reduced demand, disruptions in telecommunication networks or system failures, our ability to successfully complete and integrate potential acquisitions, liability for damages related to battery service agreements, the success of the companies in which Britishvolt has made strategic partnerships, withdrawal or expiration of governmental fiscal incentives, political instability and regional conflicts, legal restrictions on raising capital or acquiring companies and unauthorised use of our intellectual property and general economic conditions affecting our industry. In addition, please note any forward-looking statements contained herein are based on assumptions we believe to be reasonable as of the date of this press release.

For more information please contact:

Source: https://www.britishvolt.com/news/britishvolt-selects-btr-as-synthetic-graphite-anode-supplier-production-powered-on-hydroelectricity/