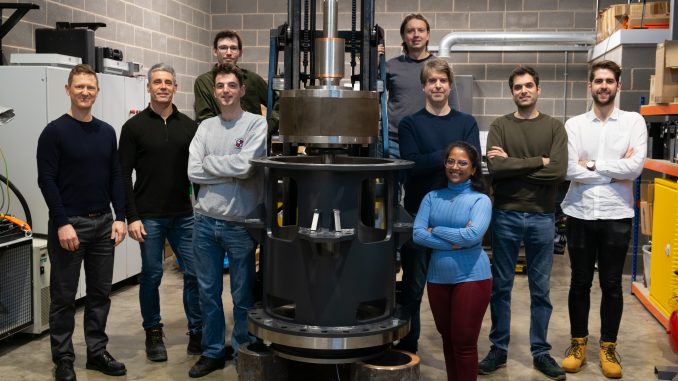

Levistor, the UK company that is developing a low cost and durable energy storage technology that will facilitate the roll-out of ultra-rapid EV charging infrastructure, has expanded its engineering team with six new appointments, including Rob Fallon who has been appointed Engineering Manager.

Rob Fallon has joined Levistor from Bowman Power Group where he held a range of senior design and engineering roles, in particular in the area of high-speed engineering systems. Before Bowman, Rob worked at Rolls-Royce.

Levistor, based in Raynes Park (south-west London), has also appointed Amir Javid, an electrical engineer with ten years of experience of high-speed machinery, and Ben Scholes who has worked for a number of years on the design and development of advanced electric motors. Ben has a Masters in Mechanical Engineering from Newcastle University. In addition, Levistor has recruited three engineering graduates, Noah Robinson (from Imperial College, London), James Baker (from Imperial College) and Nikitha Rajendran from Edinburgh University.

Matt Journee, Chief Executive of Levistor said: “The arrival of Rob and his colleagues will enable us to push forward with the manufacture and commercial application of our technology. Rob, in particular, is highly experienced in the design and manufacture of high-speed rotating machinery and has a wealth of experience in building multi-disciplinary engineering teams. He will be a key player for Levistor as we move from R&D to manufacture over the next 12-18 months.”

Levsitor’s flywheel energy storage system, originally developed by City, University of London and which has received grant support from Innovate UK, Energy Systems Catapult and Highways England, provides a high-power boost just at the point-of-use when the local grid cannot provide the level of power required.

Its patented technology will give EV drivers 100 miles of charge in just 5 minutes, making EV charging as quick and as easy as filling-up. The technology allows ultra-rapid charging to be installed in areas where the grid is too expensive or impractical to upgrade and is 50% cheaper than the Li-ion battery alternative. Levistor installations will reduce the risk of having EV deserts in the UK, help build consumer trust in using EVs to make longer journeys and thereby accelerate the switch to EVs.

Matt Journee added: “Our advanced technology puts an end to range anxiety among EV drivers and so will encourage more motorists to buy EVs earlier than being currently forecast.”

As well EV charging, Levistor is also exploring other areas where its flywheel storage technology can be used including managing peak-power demands for engineering and manufacturing applications. These areas of industry require fast, high-power energy storage and discharge that must cycle again and again, without degrading.

For further information

Levistor – www.levistor.com

Matt Journee, Chief Executive: 07493 395223 / m.journee@levistor.com

Tom Andrews, Chief Commercial Officer: 07740 195562 / t.andrews@levistor.com

Paul Taylor, Taylor Keogh Communications: 07966 782611 / paul@taylorkeogh.com

Notes to Editors

- How does our flywheel storage technology work: our system stores up energy from the grid when there are no vehicles on the forecourt or at the depot. It will supply that stored energy at high speed to electric vehicles upon arrival. The kinetic energy system (a “mechanical battery”) stores energy in a rotating shaft; electrical energy is added through an electric motor (speeding up the shaft) and taken out through a generator (slowing down the shaft).

- Levistor’s technology stores up energy from the grid at times of low demand and this energy is released at high speed to EVs when drivers arrive at the chargepoint and are needing a super-fast charge. Levistor’s technology will give an EV driver 100 miles range with just a 5 minute charge.

- The Levistor flywheel can be easily connected to the local grid and can be quickly deployed above or below ground singularly or in multiples. This makes them ideal for service stations, tourist destinations, bus/rail termini, fleet depots and distribution centres (for example supermarket deliveries and general retail).

- According to Capital Economics, it will cost up to £45bn to upgrade the UK’s grid to meet the demand of EVs, whilst the cost of grid connections can be particularly expensive in remote locations. As ultra-rapid charge-points use significant power, they could result in the need to upgrade a sub-station – this could cost over £500k. Also, the time taken to upgrade power connections can be extremely long; upgrading to a 1MW connection can take up to a year and in some cases even longer (if a cable needs to cross Forestry Commission land or Network Rail land, the planning process can take another year).

- The CMA report (EV Charging Market Study, July 2021) said (para 4.16) that significant investment is needed to improve the quality and reliability of charge points to meet likely EV charging demand at MSAs. To do so, investment is needed both in the charge-points themselves but also more significantly, in the electricity network infrastructure to provide increased electricity supply. Estimates indicate that the equivalent of 2300 ultra-rapid charge points are needed at English MSAs by 2030 (there are around 500 rapid and ultra-rapid changepoints at MSAs in the whole of the UK today).

- Levistor Ltd is a private company to commercialise its kinetic energy storage technology for grid power boosting. It is the only known, fail-safe flywheel with a simple, low-cost steel construction that can spin faster for greater energy storage.